Largest DeLaval free-flow robotic milking barn in North America

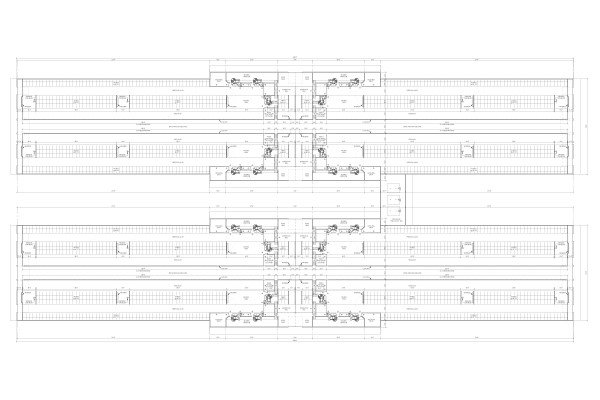

It will consist of two expanded/retrofit freestall barns of 12 Voluntary milking system VMS™ robots, for a total of 24 VMS. Join us on a virtual walk-through of this setup to see how comfortable these 1600 cows will be in their new home.

Summary:

- 2 buildings of 12 VMS, for total of 24

- Expansion/retrofit of existing freestall barns

- Free flow cow traffic

- 6-stall rows, 3-stall rows/group

- Center drive-through feed lane

- Automatic sorting with return to robot

- Fresh/hospital/non-robot cows milked in current parlor

The robots are arranged in an L-shape with two in one room along the sidewall and one in its own room on the crossover aligned with the head-to-head row of freestalls. Being an expansion/retrofit of a center drive-through barn means that locating all robots in one room is not possible. However, we were still able to stay within acceptable limits for milk transport, cleaning, and a potential upgrade to the VMS Supra+. The arrangement of robots makes this possible.

The L-shape also makes cow fetching an easier job as we now have two fetch pens, one for each alley. The primary fetch pen is along the sidewall and serves the freestall alley while the other is adjacent to the single VMS and serves the feed alley. The latter also doubles as the return waiting area so cows from the separation pen can still be milked.

The arrangement of robots allows for shared clear space thereby preserving more stalls in the existing barn. It’s important to follow recommendations for clear space in order to minimize congestion in front of the robots, which can lead to reduced visits. We like to see at least 20 feet before an obstacle.

Sorting cows from each robot is still possible and we always encourage sorting be a functionality that is incorporated from the early design stages. A dairy won’t typically sort many cows on a daily basis (if everything is running right) but it will certainly be put to use. In this case there will be lock-ups along the feed wall in the main milking groups for general herd health checks while the separation pen will be the place for hoof trimming, udder singeing, or other less frequent activities.

It’s worth pointing out that cows from the furthest robots from the center of the barn will be sorted through the adjacent robot on their way to the separation pen. It is very important to ensure there is enough space for one cow in the lane between the robots as there may be a short wait to pass through the other robot.

At DeLaval our focus for every VMS facility is absolutely on cow comfort and cow traffic while keeping the economics in mind. Many years of experience and lessons learned have all truly come together in this particular design and we are very excited to see this project come on-line. And, with excellent dairy management, I’m confident it will be one of the best robot barns to date and pave the way for future innovations.