DeLaval VMS™ V300: A new experience for cows and farmers

The DeLaval Voluntary Milking System VMS™ V300 was designed to help milk producers go toe-to-toe with challenges like animal welfare, farm profitability, work efficiency and food safety. Not only is the redesigned VMS a smarter robot powered by a new software with remote connectivity, but it features several significant upgrades, including a new teat preparation and attachment system and a completely redesigned milking module for higher level of hygiene.

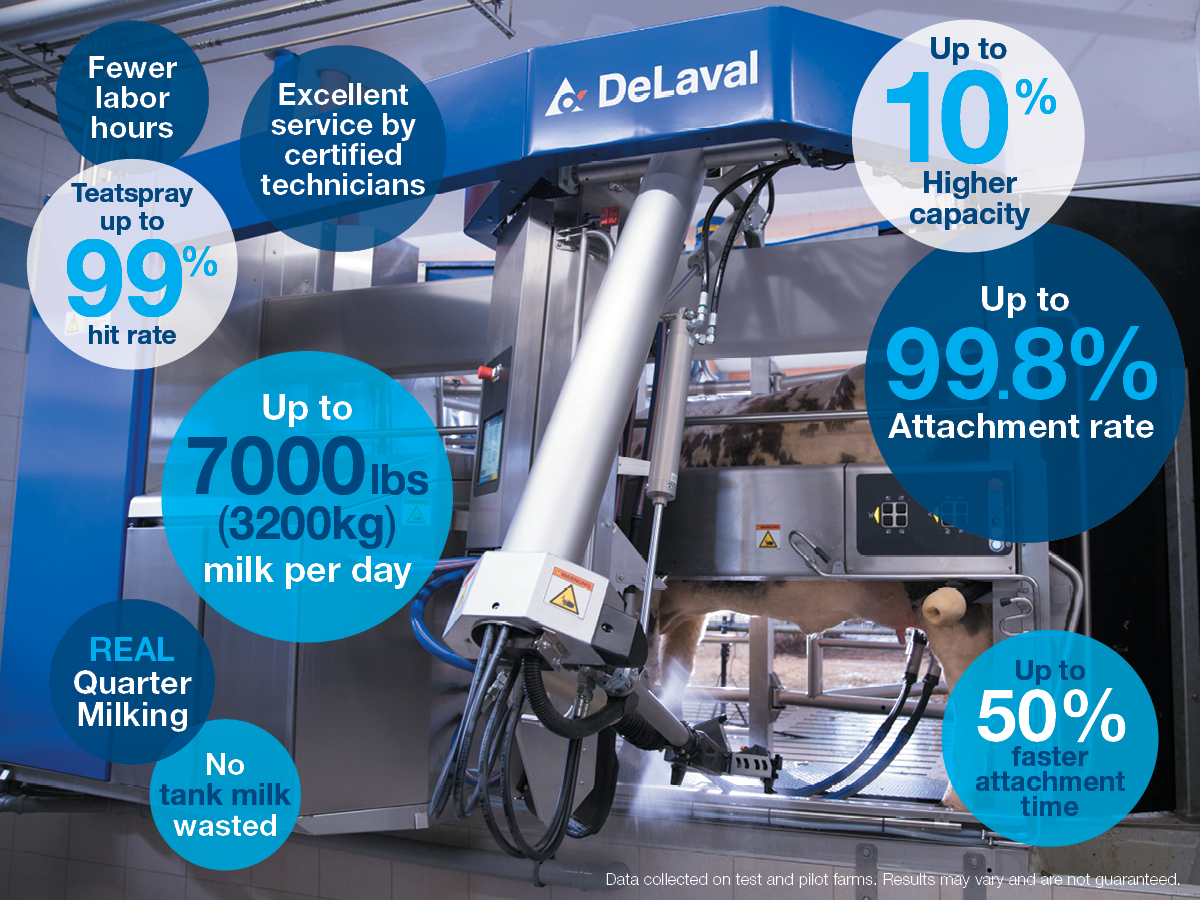

With all of these improvements, the DeLaval VMS V300 challenges the status quo of efficiency by reducing box time per milking by 40 to 60 seconds.

DeLaval InSight™

The key technology which makes our redesigned VMS smoother, faster and more accurate cleaning, preparing, treating, attaching and spraying possible is called DeLaval InSight™. Equipped with a state-of-the-art vision system consisting of a new teat-locating software with proprietary algorithms and a self-cleaning time-of-flight (ToF) camera, the VMS V300 maps and learns each cow’s udder and teat placement – from the very first milking! You won't need to spend time teaching the teat positions the first time a cow comes through.

These innovations amount to an effective attachment rate of up to 99.8 percent and a teat spray hit rate up to 99 percent.

DeLaval PureFlow™

The milking module and cleaning system of the VMS V300 robot has been completely redesigned to deliver a quality and safe product. It’s not just about cleaning teats and preparing them for optimum milk letdown, but what’s equally important is maintaining the integrity of the food supply.

The exclusive, transparent cup allows you to see PureFlow in action, individually cleaning and stimulating each teat to improve productivity – resulting in up to 14.5 percent faster milk flow rates.

The DeLaval PureFlow system also separates the foremilk, which is removed to a waste container via a separate line. Once milking is complete, the cup is fully flushed and cleaned as part of the comprehensive cleaning routine that the VMS V300 automatically carries out. The cleaning process is now up to five minutes faster and uses 5.4 gallons less water.

DeLaval InControl™

With DeLaval InControl™ you are never out of touch with what is going on at your farm. It doesn’t just make it easier to control and monitor your DeLaval VMS V300, DeLaval InControl provides you with simple visual reports, analytics and information to help you to make better farm management decisions. DeLaval InControl means you can call up the performance of a cow, see throughput statistics or change the settings of your system.

Best of all, it delivers this functionality to you, wherever you want it. Using either the touchscreen or a mobile device, you are always able to view your DeLaval VMS V300 to control its operations, track daily routines, update individual cow data or share information with staff.

Click here to learn more about improved decision making with DeLaval InControl.

Better performance, same dependability

The DeLaval VMS V300 was designed to take automated milking to the next level, but it’s still the dependable workhorse you can rely on – built to be robust enough to handle the challenging environment of a dairy barn. When it comes time to perform regular maintenance on your VMS V300, the unit also features excellent serviceability.

Contact your dealer today to learn how your farm could benefit from the latest DeLaval innovation.

**All data collected on test and pilot farms, actual results may vary and are not guaranteed.