Changing the Way Barns are Designed

Freestall barn

With a fast and accurate attachment system, the DeLaval VMS V300 can potentially milk 70 cows. The unmatched capacity of the V300 means we’re changing the way barns are designed by increasing the number of stalls per robot in the bedding area.

Around the robot

How do you design your dairy facility for what could be 70 cows flowing through the robot? Using either free-cow traffic or guided traffic, the dairy facility needs to allow cows to flow comfortably from one area to the next. Combining wide alleys and large crossovers with water and swinging cow brushes help cows move freely. But when it’s time to be milked, are they competing for space?

In a toll gate-style guided traffic design, only cows with milk permission have access to the area entering the V300. A smart selection gate at the entrance can control the number of cows in this pen. All cows not selected to enter the commitment pen have free passage to the feed table. Since milked cows are exiting away from the commitment pen, there is less competition for space at the robot entry point allowing cows to flow through the V300 more efficiently.

Robot room

The recommended VMS room design has changed to suit the new V300. Although there are many different variations and adaptations of VMS rooms on dairies, there are a few new design standards for the V300.

Even though the floor elevation inside a VMS room does not have to be recessed, a 16 to 21 inches recess is recommended for the V300. This elevation is slightly less than we’ve seen on many past VMS classic installations. The recommended ceiling height for the V300 room is approximately 12 feet. However, this can be reduced if other measures are taken to allow for service.

The biggest design change in a V300 installation is the location of the robot in conjunction with the wall surrounding it. We recommended moving the surrounding wall in (or the V300 out) approx. one foot so that the position of the robot is further outside the VMS room. Moving the V300 out will allow for a more open entrance and exit area, generating better cow flow through the V300.

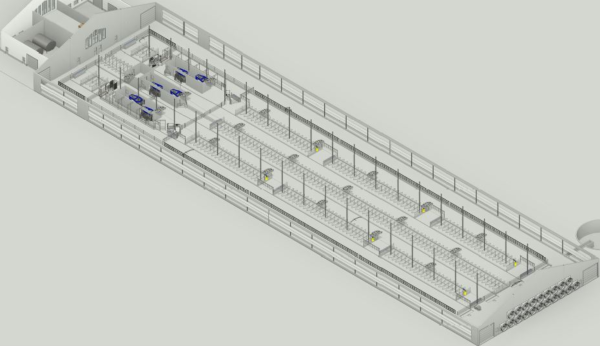

VMS V300 Barn Design Example

Description

Number of V300 robots: 6

Milking cow capacity: 422

Number of stalls: 422

Building dimensions: 492’ x 133’

Ventilation type: Hybrid (natural & tunnel)

Cow traffic: Modified guided

Manure system: Alley scrapers & cross gutter w/ box scraper to transfer pit

Other tech: Swinging cow brushes (6); sort gates; footbath; OptiDuo feed refresher

Bonus: 3-way sort gate at commitment pen can be changed to move cows through footbath or sort for special needs