Combinando tradición e innovación: DeLaval VMS™ Batch Milking

El auge mundial del DeLaval VMS™ Batch Milking

A medida que los ganaderos buscan formas más eficientes de gestionar rebaños más grandes, el DeLaval VMS™ Batch Milking, que utiliza robots de ordeño automatizados para ordeñar a las vacas en grupos a horas programadas, está ganando popularidad rápidamente.

Diseñado pensando en las explotaciones lecheras medianas y grandes, este sistema simplifica las rutinas diarias, combinando la automatización con la estructura del ordeño tradicional. Ofrece un enfoque sencillo y predecible que encaja con muchos ganaderos, integrándose fácilmente con las prácticas existentes, al tiempo que mejora el entorno de trabajo, lo que lo convierte en una opción excelente para la ganadería lechera moderna.

Descubre las revolucionarias ventajas del DeLaval VMS™ Batch Milking directamente desde Texas. En este vídeo podrás ver cómo este eficiente sistema está transformando las explotaciones lecheras.

Los resultados individuales pueden diferir; la información no constituye garantía de servicio o rendimiento. Los resultados de los testimonios no han sido verificados de forma independiente y DeLaval no garantiza que todos los usuarios obtengan los mismos resultados.

¿Qué es el DeLaval VMS™ Batch Milking?

El DeLaval VMS™ Batch Milking es un sistema que utiliza robots de ordeño DeLaval VMS™ V300 para ordeñar vacas en grupos a horas programadas. Al automatizar el proceso de ordeño, se reduce la necesidad de intervención humana, al tiempo que se permite a los ganaderos mantener el control sobre sus horarios de ordeño y alimentación, conservando la regularidad de las rutinas de ordeño tradicionales.

Los robots de ordeño VMS se encargan de tareas como la preparación de la ubre antes del ordeño, consistente en: pre-desinfección, lavado con detergente, despuntado y secado de los pezones; el ordeño en sí, es decir la colocación de las pezoneras, el sellado post ordeño y la desinfección de las copas después del ordeño. Además de controlar la salud de las vacas y recopilar datos esenciales, incluida información sobre producciones y flujos, y calidad de la leche. A diferencia de la configuración estándar del VMS, que permite ordeñar a las vacas en cualquier momento, el DeLaval VMS™ Batch Milking funciona según un programa establecido. Esto facilita las tareas a los ganaderos, manteniendo sus rutinas básicas y fusionando la comodidad de la automatización con la fiabilidad de una rutina de ordeño tradicional.

Ordeño programado

Los ganaderos establecen un horario de ordeño predecible para grupos de vacas

Eficiencia robótica

Los robots VMS V300 se encargan de todas las tareas de ordeño, reduciendo al mínimo la necesidad de mano de obra

Control de la granja

Los ganaderos mantienen la supervisión de los procesos de alimentación y ordeño

¿Cómo funciona DeLaval VMS™ Batch Milking?

- En las granjas, las vacas generalmente están separadas en grupos o lotes en función de factores como la fase de lactación, los niveles de producción, planes de alimentación, etc.

- A continuación, estos grupos se llevan a un centro de ordeño con múltiples robots de ordeño DeLaval VMS™ dispuestas en un esquema similar al de una sala de ordeño con un área de espera con capacidad suficiente para el grupo de mayor volumen de animales (aunque lo óptimo es que los grupos sean de tamaño similar).

- Cada grupo de vacas se ordeña bajo las mejores condiciones con las rutinas de preparación y ordeño automatizadas realizadas por los robots de ordeño DeLaval VMS™.

- A medida que las vacas se van ordeñando y hay capacidad en la sala de espera, se cargará el siguiente lote para unos tiempos de ordeño más eficientes. Tras el ordeño, las vacas salen a través de puertas de selección que las dirigen a la zona adecuada, como una zona de separación para posterior tratamiento o revisión, una zona particular como la de maternidad a su establo y grupo de origen o la siguiente zona de pastoreo.

- El equipo se lava automáticamente a fondo después de cada sesión de ordeño para mantener la alta calidad de la leche. A la vez que después de cada animal se hace un lavado y desinfección de las pezoneras, haciendo de cortafuegos para mantener la salud de ubre.

- El proceso se repite en la siguiente sesión de ordeño, pudiendo ordeñar los mismos lotes o hacer alteraciones, ordeñando solo aquellas vacas de alta producción para mejorar rendimientos. Esta configuración permite a las granjas mantener sus rutinas y prácticas de alimentación actuales, facilitando una transición más fluida al ordeño automatizado. Las vacas pueden ordeñarse 2, 3 o 4 veces al día, en varias sesiones de ordeño.

¿Cuáles son las principales ventajas del DeLaval VMS™ Batch Milking?

El DeLaval VMS™ Batch Milking fusiona las prácticas tradicionales con la tecnología robótica moderna, lo que permite una gestión eficaz de rebaños más grandes con menos esfuerzo manual. Este método optimiza el uso de recursos, como la mano de obra, el agua y la energía, operando solo cuando es necesario, lo que contribuye a la sostenibilidad desde la ubre hasta el tanque.

Integración perfecta

El cambio al DeLaval VMS™ Batch Milking es sencillo: mantienes tu gestión actual de las vacas y las prácticas de alimentación con ración mixta total. Las vacas se adaptan rápidamente a la nueva rutina, lo que minimiza la necesidad de una amplia formación de los empleados.

Simplicidad para las grandes explotaciones

Agiliza las operaciones de las grandes explotaciones lecheras, eliminando las dificultades del ordeño manual. Esto facilita la gestión de rebaños más grandes, reduce el estrés del personal, garantiza unas operaciones diarias más fluidas y mejora la gestión del tiempo.

Vacas más sanas

Los robots de ordeño DeLaval VMS™ están diseñados para ser suaves y precisos. Eliminando el sobre-ordeño, ayudan a una higiene óptima y reducen el estrés con un proceso de ordeño tranquilo y constante. Este enfoque en vacas más sanas mejora la calidad de la leche y aumenta la productividad de la explotación.

Infraestructuras preparadas para el futuro

Diseñados para adaptarse a los avances tecnológicos, puedes ampliar o actualizar fácilmente tus sistemas robóticos a medida que surgen nuevas innovaciones, lo que garantiza que tu inversión siga siendo relevante y rentable.

Mejor aprovechamiento del capital

Los robots pueden ordeñar casi el doble de vacas por hora que los sistemas tradicionales, maximizando la inversión de capital. Esto permite a los ganaderos aumentar la productividad sin el correspondiente aumento de costes.

Mayor sostenibilidad

Ayuda a maximizar la sostenibilidad optimizando el uso de mano de obra, agua y energía, al tiempo que ayuda al bienestar de las vacas mediante un funcionamiento eficiente y responsable.

Società Agricola F.lli Aceto

Renato Aceto, uno de los propietarios de la Società Agricola F.lli Aceto de Calabria (Italia), explica por qué decidieron pasarse al DeLaval VMS™ Batch Milking. «Empezamos a pensar con originalidad y desarrollamos este sistema innovador», afirma. Al principio, no estaba seguro de cambiar al robot de ordeño DeLaval VMS, pero pronto descubrió que sus preocupaciones era una natural aversión al cambio, desvaneciéndose desde el primer ordeño. En última instancia, la decisión se vio impulsada por la facilidad de uso del sistema, su potencial de crecimiento y la posibilidad de mantener su actual sistema de recepción de piensos. Con la introducción de ocho unidades del robot de ordeño DeLaval VMS V300, ahora están preparados para ampliar su explotación a más de 480 vacas en solo tres años.

Los resultados individuales pueden diferir; la información no constituye garantía de servicio o rendimiento. Los resultados de los testimonios no han sido verificados de forma independiente y DeLaval no garantiza que todos los usuarios obtengan los mismos resultados.

¿En qué se diferencia de los montajes de robots VMS tradicionales, las salas de ordeño y las rotativas?

Montajes de AMS/VMS tradicionales

A diferencia de los montajes AMS/VMS tradicionales, en los que las vacas tienen libre acceso a los robots y eligen sus propios horarios de ordeño, el DeLaval VMS™ Batch Milking funciona según un horario fijo. Este enfoque lleva a las vacas a la zona de ordeño en grupos, lo que agiliza el proceso de ordeño y mejora la eficiencia, especialmente en explotaciones de tamaño mediano-grande.

Si consideras que los montajes AMS tradicionales son la alternativa ideal, ten en cuenta estas ventajas del DeLaval VMS™ Batch Milking:

- Mantén una alimentación TMR rentable mientras ordeña automáticamente.

- Consigue la separación de las vacas y la separación de la leche en un solo lugar.

- Los cubículos permanecen vacíos durante el ordeño para la gestión de las camas.

- No es necesario ir a buscar a las vacas entre ordeños. En los sistemas de tráfico libre de vacas, entre el 5 y el 10% de las vacas necesitan ser traídas para el ordeño al menos dos veces al día.

- No se necesitan refuerzos las 24 horas del día para gestionar las alarmas.

- No es crítico si uno de los robots deja de funcionar, ya que tiene otros en el mismo lote.

Salas paralelo y rotativas

Aunque las salas de ordeño tradicionales y las rotativas siguen un horario, a menudo requieren más trabajo manual para tareas como colocar las unidades de ordeño. El DeLaval VMS™ Batch Milking ofrece mayores niveles de automatización y recopilación de datos, lo que permite una mejor supervisión de la salud del rebaño y una mejor gestión de la salud de la ubre para una toma de decisiones informada.

Si utilizas ordeño en sala o rotativa, ten en cuenta las siguientes ventajas del DeLaval VMS™ Batch Milking:

- Seguirás gestionando y alimentando a tus vacas como hasta ahora, solo que el ordeño es realizado autónomamente por robots.

- El ordeño automático proporciona una rutina consistente, eliminando la necesidad de formar a nuevos empleados.

- Las vacas están más tranquilas gracias a un entorno de ordeño menos estresante.

- Es fácil ampliar o actualizar los robots a modelos más nuevos en el futuro.

- Optimizas la inversión de capital, ordeñando casi el doble de vacas por hora y por robot en comparación con los sistemas de sala de ordeño o rotativas.

¿Qué explotaciones son las más adecuadas para el DeLaval VMS™ Batch Milking?

A medida que aumentan los costes de la mano de obra y se hace más difícil encontrar personal cualificado, el DeLaval VMS™ Batch Milking reduce la dependencia del trabajo manual, lo que permite al personal centrarse en supervisar las operaciones y responder a las notificaciones del sistema en lugar de realizar tareas rutinarias. Liberando tiempo de su día a día para otras tareas de mayor importancia y rentabilidad que colocar pezoneras.

Ideal para granjas con 500–2000 vacas

El DeLaval VMS™ Batch Milking es el más adecuado para explotaciones medianas y grandes con rebaños de 500 a 2.000 vacas. La gestión de un número tan elevado de vacas puede requerir mucho tiempo y mano de obra. El DeLaval VMS™ Batch Milking automatiza el proceso de ordeño, ahorrándote tiempo y optimizando tus recursos.

El sistema proporciona datos valiosos para controlar la salud del rebaño, la producción de leche y la alimentación, lo que te permite controlar el rendimiento de tu explotación. Con el DeLaval VMS™ Batch Milking, puedes aumentar la productividad y gestionar la mano de obra de forma más eficaz. Es perfecto para modernizar o ampliar tu explotación y se integra a la perfección con tu configuración actual.

¿Cuántas vacas se pueden ordeñar?

La capacidad de un sistema DeLaval VMS™ Batch Milking depende de varios factores, como el número de robots DeLaval VMS™, la frecuencia de ordeño (2 a 4 veces al día) y las horas de funcionamiento del sistema. Otros factores, como la genética de los animales, que incluyen la velocidad/flujo de leche de cada vaca, la raza de las vacas, y lo bien que el operador gestiona el flujo de vacas dentro del sistema.

Las capacidades suelen oscilar entre 7 y 8,5 vacas por hora y robot. El número de robots necesarios también depende del tamaño de los grupos del establo que impactará directamente en algunos de los puntos anteriormente mencionados.

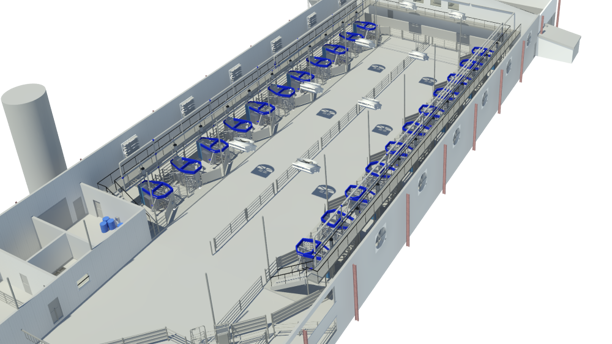

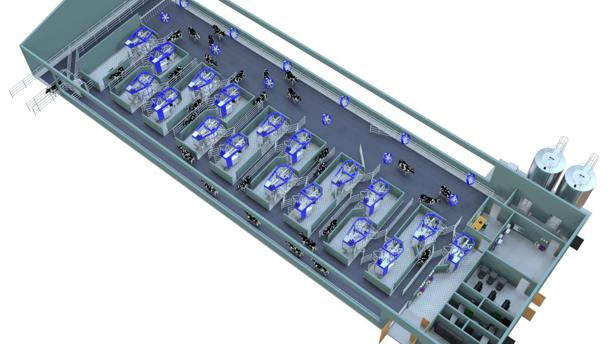

¿Cómo es una instalación DeLaval VMS™ Batch Milking?

El diseño de las instalaciones DeLaval VMS™ Batch Milking puede variar enormemente. Algunas explotaciones optan por configuraciones rentables, mientras que otras dan prioridad a los sistemas de alta eficiencia. La flexibilidad de los sistemas VMS los hace adaptables a granjas de varios tamaños, siempre que se lleve a cabo una cuidadosa planificación y diseño.

Una configuración de DeLaval VMS™ Batch Milking bien diseñada busca el equilibrio entre eficiencia y flexibilidad. Suele incluir áreas de espera de entre 5 y 7,2 metros de anchura, equipadas con puertas automáticas o manuales para gestionar eficazmente el tráfico de vacas.

Las granjas pueden implementar diferentes disposiciones en función de sus necesidades específicas. Por ejemplo:

• DeLaval VMS™ situados en una línea: esta configuración cuenta con un área de espera estrecha con ordeño en una línea. Una granja para 14 robots de ordeño DeLaval VMS™ utiliza una zona de espera más estrecha. En esta configuración, las vacas entran, por un lado, y salen por el otro, lo que ayuda a agilizar el proceso de ordeño.

• DeLaval VMS™ situados en dos líneas paralelas: en este diseño el área de espera es consecuentemente más amplia para admitir las vacas de la doble línea de ordeño. Algunas granjas usan esta configuración para reducir espacio longitudinal. De este modo, las vacas acceden a un área de espera central y salen hacia los extremos, consiguiendo una mayor eficacia del espacio, reduciendo longitud de la huella de la zona de ordeño.

• DeLaval VMS™ situados en “U”: en esta configuración, al igual que en la anterior, se minimiza el impacto de la huella de la zona de ordeño, quedando reducida a la mínima expresión, teniendo 3 laterales ocupados con robots de ordeño, consiguiendo que el Delaval VMS™ Batch Milking sea lo más reducido en espacio, pero manteniendo todas sus ventajas.

Está claro que cada uno de estos diseños se adecuara mejor o peor dependiendo de la planta de tus edificaciones. Es por ello que la planificación es esencial y para ello nuestro equipo te aconsejará según tus necesidades.

• Puerta empujadora: algunas granjas utilizan una puerta para controlar el flujo de vacas. Sin embargo, esto puede limitar las oportunidades de ordeño al restringir el acceso de las vacas a los robots. Para facilitar el flujo de vacas y dependiendo del diseño se aconseja el uso de puertas unidireccionales de dedos, que pueden delimitar zonas e igual que las empujadoras pueden automatizarse y ser elevadas de forma remota. Las zonas de estabulación bien organizadas pueden eliminar la necesidad de utilizar puertas empujadoras, garantizando una actividad más fluida y eficaz.

Robert Jensen, Especialista en DeLaval VMS™ Batch Milking, comparte sus conocimientos y puntos de vista sobre este tema.

"A medida que crece el tamaño de los rebaños, factores como la simplicidad, la previsibilidad y la eficiencia operativa cobran cada vez más importancia, y es aquí donde destaca el DeLaval VMS™ Batch Milking."