Características principales

DeLaval DelPro™

Decisions start here

It isn’t enough that the DeLaval VMS™ Series is our best of breed milking systems. It is essential that it is capable of forming the central hub for your entire farm, and that’s where DeLaval DelPro™ comes to the fore.

We have built DelPro and its suite of sensors and applications to give you more control than we have ever given you before, by surrounding you with faster, more accurate access to valuable information, analysis and reports that will help you make better decisions on your farm.

DeLaval InControl™

DeLaval InControl™ doesn’t just make it easy to control and monitor your DeLaval VMS™ ; it will provide you with simple visual reports, analysis and information to help you to make better decisions. DeLaval InControl™ means you can call up the performance of a cow, see throughput statistics or change the settings of your system.

Best of all, it delivers all this functionality to you, wherever you want it. Using either the touchscreen or a mobile device, you are always able to view your VMS™, to control its operation, track daily routines, update individual cow data or share information with staff.

Quickly and easily view:

- Cow queue to VMS™

- Individual cow status and performance data

- Find my cow in the barn or pasture

- Recently milked cow info

- Activity monitoring information

- Somatic cell count information

- Fine-tune individual cow settings

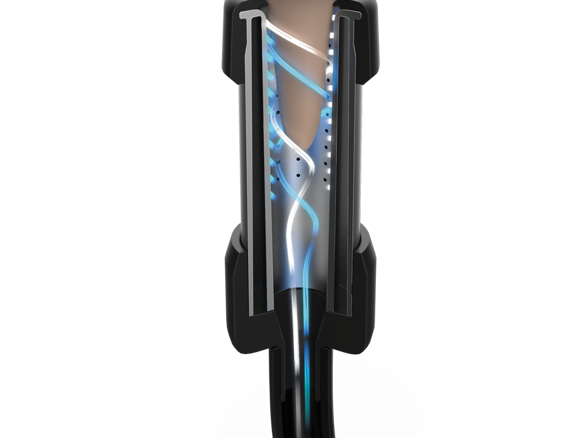

DeLaval PureFlow™

The start of the most gentle and effective milking process we’ve ever created.

- Better hygiene

- Stimulation

- Adjustable settings

- Transparent cup

- Soaps can be added

It all starts with preparation - PureFlow doesn't just clean udders, it also prepares them. Using the exclusive transparent cup that lets you to see the action, each teat is individually cleaned and stimulated to improve let-down and productivity.

Add to this the separation of pre-milk, which is removed to a waste container via a separate line, and fully adjustable settings including the ability to add soap for enhanced cleaning, and you have the ultimate preparation. Once milking is complete, the cup is fully flushed and cleaned as part of the comprehensive cleaning routine that is automatically carried out by the VMS.

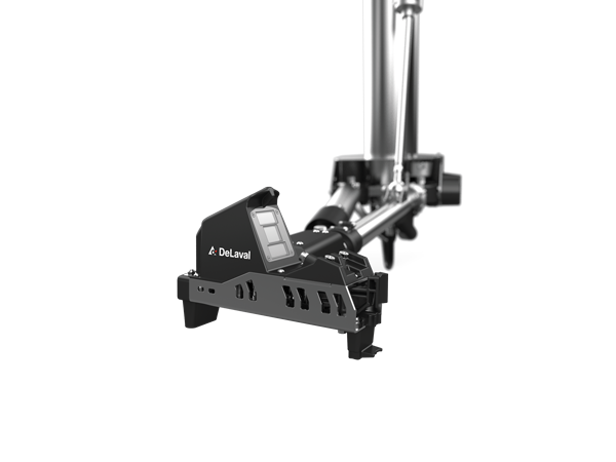

DeLaval InSight™

- Smoother and faster

- Two nozzles for sprays

- Self learning

When you observe a DeLaval VMS in operation there are two things that strike you immediately. How calm the cows are, and how gently and smoothly the robotic arms go about the repetitive tasks of cleaning, preparing, treating, attaching and spraying.

The key technology that makes this possible is InSight. What you see is the smoothest, fastest and most accurate arm that we’ve ever created. Driving this performance is the interplay of our most sophisticated camera, hardware and software ever seen in a milking environment.

DeLaval RePro™

32% improvement in insemination rate*

- Automatic pregnancy check

- Detect abnormal reproduction cycles

- Even detects silent heats

- Notification of early abortions

- More productive lactations

- Fewer open cows

- Reduced culling

RePro turns the ultimate milking and animal welfare system into a reproduction management tool as well. By providing a clear picture of each animal’s reproductive status using DeLaval DelPro™ BioModels, progesterone levels are taken automatically in milk samples. All critical reproduction questions can be answered automatically with notifications within your DelPro Applications. All of this adds up to healthier cows, reduced vet costs, improved AI costs. Having cows become pregnant at the right time will result in more productive lactations – which means more money.

* Data from VMS V310 pilot farms.