How to analyse your milking performance in DelPro™ FarmManager

Because time is your most precious resource – get your cows milked in the most efficient way

Our DeLaval milking systems are equipped with sensors that record cows entering and exiting a parlour and all operations in the middle of the milking process. Rather than having individual data points of the milking sessions DelPro combines all the data recorded; turns it into performance information and presents it to you in an easy to understand manner.

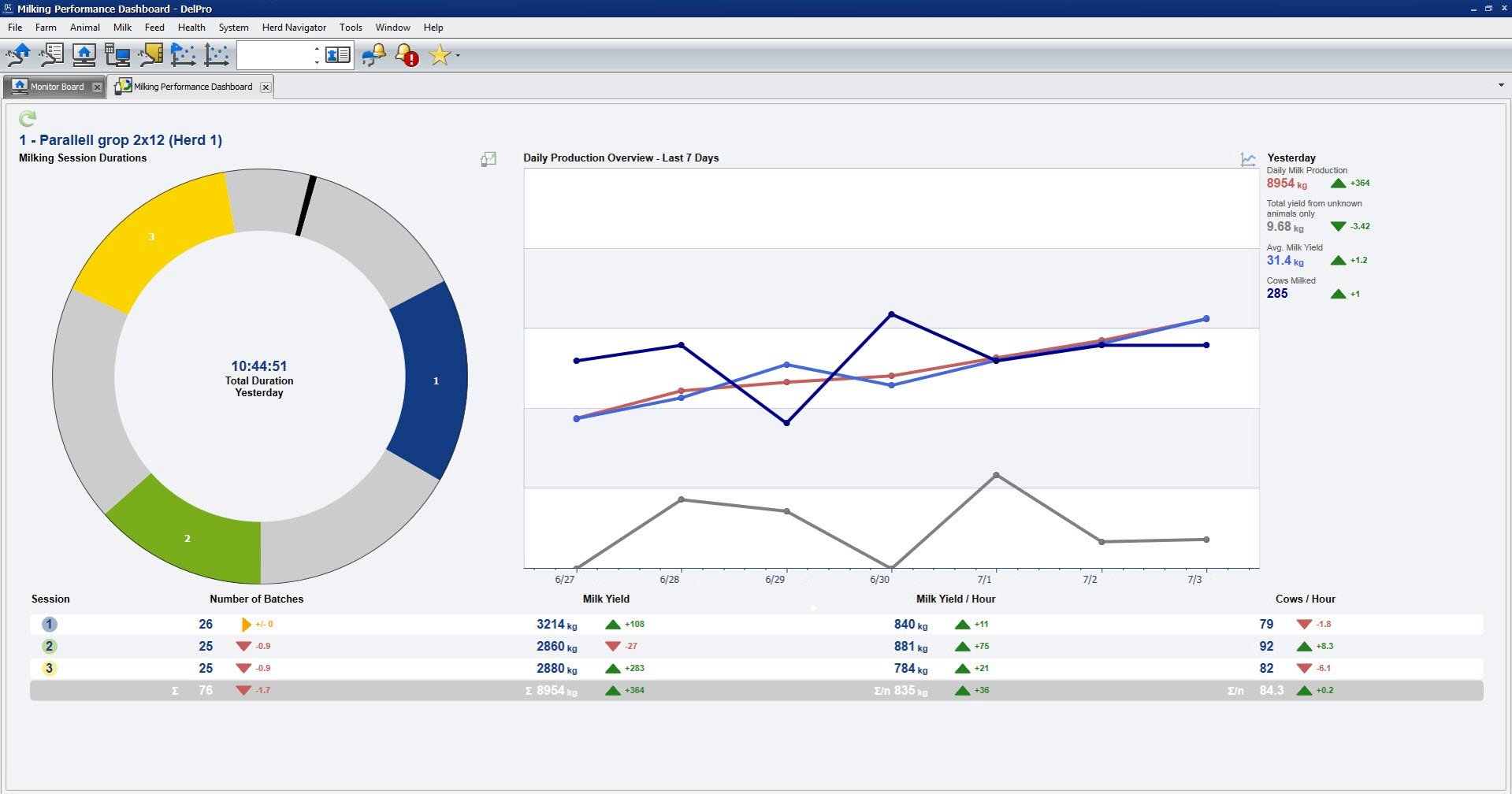

With the DelPro FarmManager Milking Performance Dashboard you get a quick insight in the throughput of your milking system in terms of cows milked per hour (rotations and/or batches milked) and the harvested yield across the milking sessions. The performance for yesterday is compared to the average of the 7 previous days and changes are quickly highlighted by means of the coloured triangles (▼▲►).

When you believe one of the milking sessions can be improved, additional information is readily available within our top down approach to quickly find those periods within the milking where idle times occur.

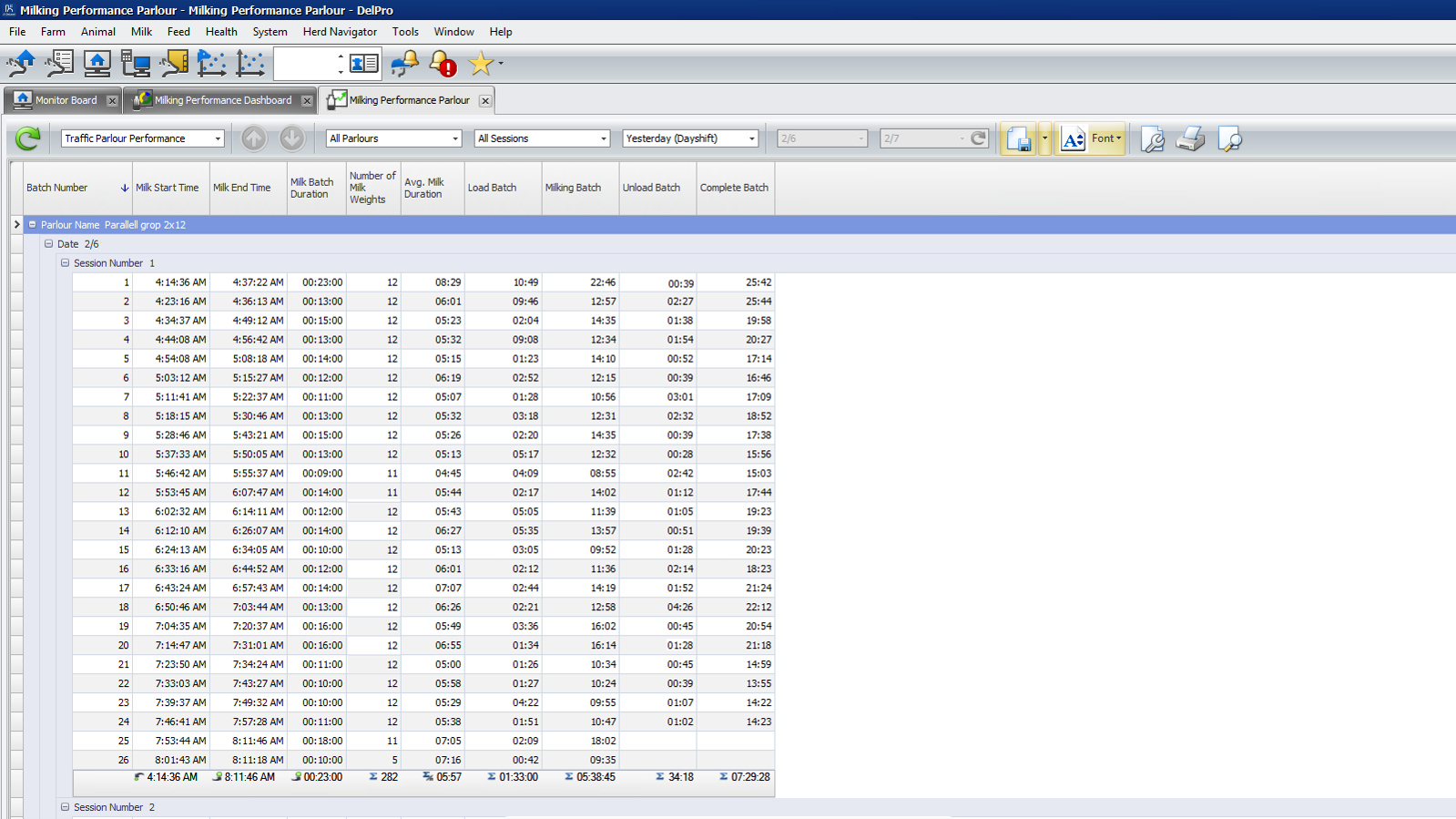

In a DeLaval parlour milking system we analyse for example the time it takes to load a batch of cows. Longer parlours will take more time to load, so working with a crowd gate can improve loading times. Also we show the time between when the last cow finished milking until the time the batch is released. This KPI shows the time potentially wasted.. You can ask yourself when this frequently happens; why are cows kept idling?

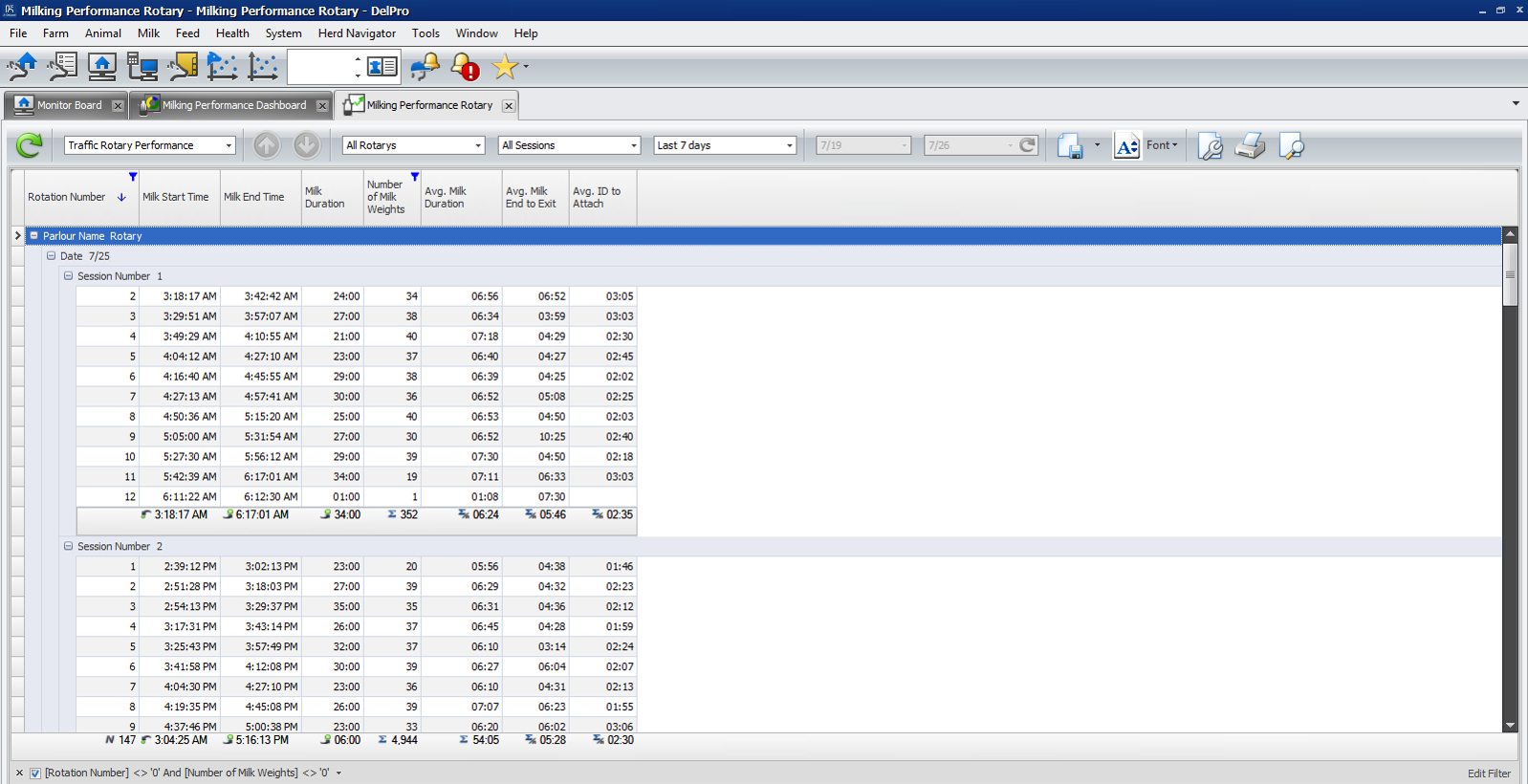

For a DeLaval rotary milking system we have information on the milk duration per rotation, the time from identifying a cow entering the rotary until attachment took place, and the time a cow is not being milked on the rotary after milking finishes. When cows are attached very quickly after entering the platform, a follow-up analysis on the milk flow, described further down, is recommended. You might see cows with bi-modal milk flows. At the end of milking, long idle times before the cows exits the platform indicate a possibility to increase the parlour throughput. the other end when you see long idle times on the rotary, where the milking is finished but the cow is still on the platform, you have a possibility to increase the parlour capacity.

For any DeLaval milking system we present incidents that occurred during each session. As an example we present manual detaches of the milking cluster. The KPI shows total number of times a cluster was removed manually - that is, the manual detach button was pressed on the MPC. This shows potential slow milkers and the milking team wants to get the cows off the platform; or exit the batch. Perhaps there is a need for a slow milkers group? On the other end, if the incidences are not related to milking speed, you will have to follow-up with the team to fond the reason for this manual detachment behaviour.

In summary, the milk performance dashboard and detailed views are the tools to optimize your milking process, reduce incidents during milkings, and saving time of your milkers and energy.

How you milk your cows is the basis for great udder health

We believe that an effective pre-milking routine is essential for a quick and gentle milk-out. In order to achieve this, your milking routines need to be perfect. Structurally implemented pre-milking routines will result in good teat end conditions, prevents over milking, and improves throughput of the milking system. As mentioned earlier we measure and present to you the time from identifying a cow entering the rotary until the cluster is attached. If this time is too short, it is already a good indication that we should also analyse the milk flow rates of the animals.

Our milk meters constantly record the milk flows of the cows during milking. This accurately recorded data is then combined on session and cow group level, and gives you an insight into the milk flows and cup-on-times throughout those milking sessions; and between cow groups.

Within the DelPro FarmManager group milk flow analyses, we provide you with a clear information on the group performances across the different milking sessions. Milk flow data is summarized in:

- Categorized flow-rates (0-15s, 15-30s, 30-60s and 60-120s)

- Milking durations per animal (cups on time in min)

- Time a cow spend during milking in low flow (<1kg/min)

- Take off flow

- Average peak flow

- Two minute yield (in kg and %)

- Milk yield per milking

- Daily yield per animal

Visually you will be able to quickly see if there is a drop in milk flow rate within the first two minutes of milking – this is called a bimodal milk flow, and should be prevented as it decreases milk efficiency, and increases damage to the teat. This tool supports you optimizing pre-milking routines between different milking shifts, milking sessions and/or cow groups – improving udder health on your farm. What you can keep in mind on improving are these three key processes:

- You’ll need 30 seconds of teat dip contact for effective bacteria kill

- Touch time, including stripping and wiping 12-15 seconds. The longer the touch time, the stronger the oxytocin impacts

- Lag time between putting on cups. Research states 30 – 45 seconds after touch, from experience we found that 60 – 120 seconds is best. 90 is ideal, and 120 later in lactation, due to there being less milk in the cistern available.