“There was little doubt that we wanted a herd that grazed, and milking with a robot was the best option because we didn’t want to be chained to a parlour twice a day."

As part of their succession planning, a family farm near Carlow chose to introduce a dairy herd by building a new shed and installing a milking robot. Four years on and a second robot has been added to milk a growing herd of 128 cows and the farm is hoping to grow to 145.

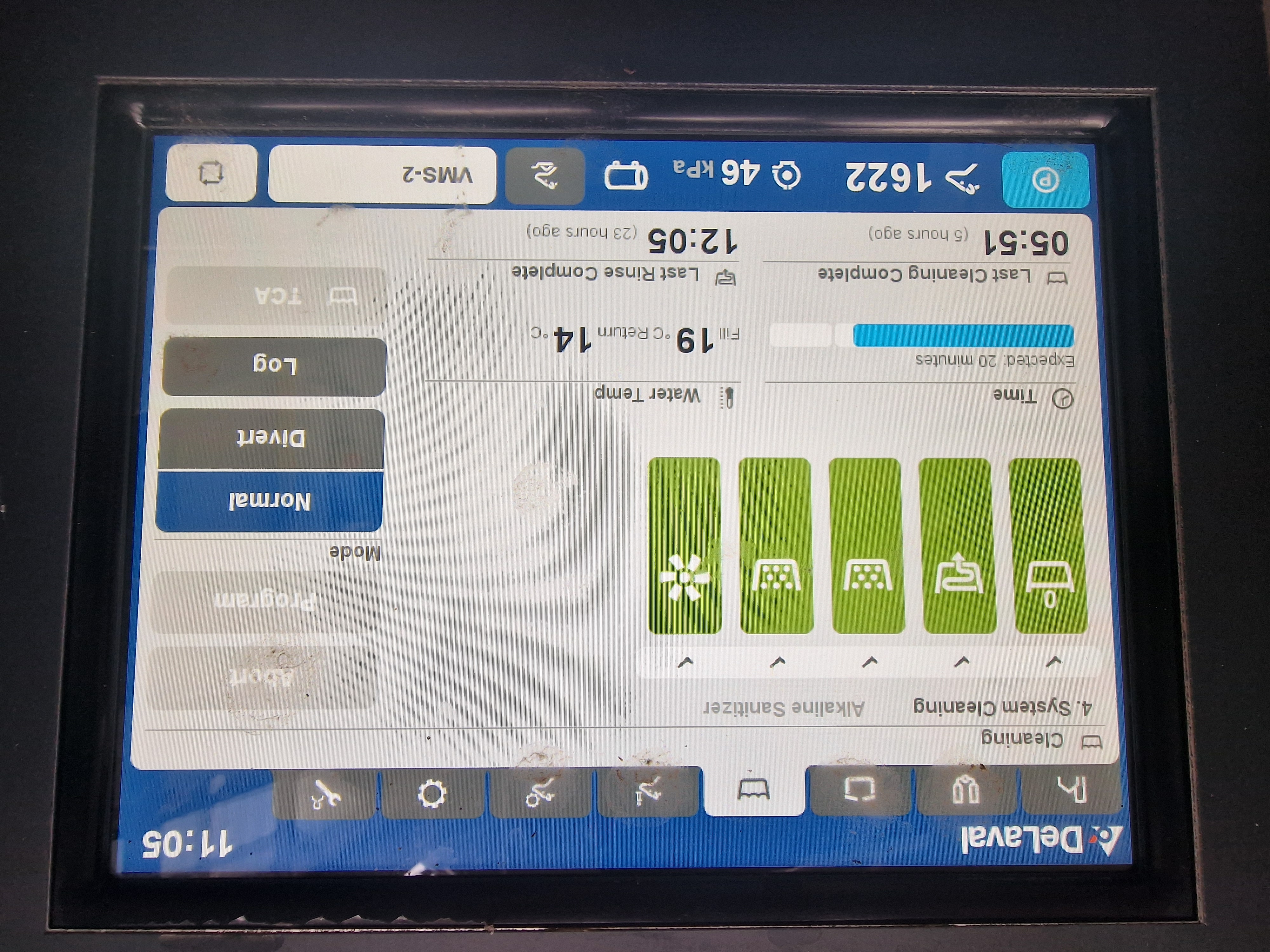

Malcolm Kidd is the fifth generation at Kidd’s Dairy in County Carlow. In his late twenties he returned home with a vision to add a dairy herd to the existing suckler beef and arable farm. Working with his father Ivan, the decision was made to introduce the dairy herd and the family started milking in 2022 with one DeLaval VMS V310 robot.

“There was little doubt that we wanted a herd that grazed, and milking with a robot was the best option because we didn’t want to be chained to a parlour twice a day. We also wanted to avoid additional labour costs, especially when relief milking staff can command up to 70 euro per milking,” he explains.

Working closely with DeLaval dealer EFS Automation, the family installed the first robot into a new shed in 2022 following two years of planning and development. To graze the cows, a series of permission gates were also installed to operate an A,B,C grazing system.

“There were costs and savings on both sides of the installation. It would have been cheaper to install a parlour, but time and labour would have put too much stress on the farm, so a robot was the better option. Coupling the robot with a grazing system enabled us to reduce our time and costs, which has enabled us to take on dairying without any additional labour,” he says.

All the cows were brought on to the farm as bulling heifers and adjusted to the robots quickly. Two years on, the herd have reached yields of up to 9000 litres per cow per year, with butter fats at 4.35% and protein at 3.6%. It is hoped that this will continue to increase as the herd matures.

“We have chosen a split calving system with 70% of the herd calving in spring, to utilise grazing grass, and the rest in autumn. When introduced to the robots, the first cows in the herd were quick to adapt to the robot because they knew no different. It took just four milkings before 95% of the herd settled in and learned the system,” he says.

The A,B,C grazing system uses a series of permission gates to move the herd between predetermined paddocks that are fenced off daily to provide sufficient forage whilst protecting the ground for regrowth. Milking permission for the cows was gradually increased from 7 kilos to 9 kilos and the herd is averaging 2.2 milkings a day.

“We fence off 1.2-1.4 acres for grazing areas A and B. C is a smaller allocation and when needed can include some buffer feeding with silage if grass is in short supply. We have 110 acres on the grazing platform, so we have to manage the land carefully but, despite the recent weather conditions which have seen us use more silage this year, we are making good milk from forage,” he explains.

The farm’s rotation includes grass for silage, grazing for youngstock and replacement heifers, wheat, oats and barley, along with 13 acres of maize. The remaining grassland is sectioned off to provide grazing paddocks.

“The maize harvest has been extremely disappointing this year because it was such a cold spring and we have had extremely heavy rainfall after sowing which without plastic led to the soil being capped. We would hope to yield 16-18 tonnes per acre but this year it was just 7.7 tonnes,” he says.

From 1 am to 9 am the cows are given access to grazing area A. A 9 am until 5 pm allocation is given to B and then the cows are given from 5pm onwards in area C. The shed is located within a relatively short distance of grazing land, with the furthest paddock being just 750 metres away.

“We started with gravel tracks but installed new roadways to improve movement and foot health for the herd. This had the added benefit of increasing milkings by 0.3 per day and we haven’t had to fetch the cows in either,” he says.

A second robot was installed when the decision was made to increase the herd. Before the installation a single robot was milking 78 cows.

“We are up to 128 in milk, having introduced 60 first lactation heifers this year for the second robot. The plan is to grow to 140, maybe 145, which will be comfortable with the two robots,” he adds.

Following the introduction of the second robot, the farm is making full use of the technology that runs alongside it. DeLaval’s DelPro system includes a progesterone testing system called Herd Navigator, which uses milk samples to detect cows in heat.

“Not having to bring the herd in to establish which cows are in heat has been a huge help because it would take hours to fetch them for tail painting and then a couple of days for them to settle back into their routine. With 78 cows on one robot, it would have put too much strain on us and the herd if we didn’t have the technology,” he says.

Working with Herd Navigator since the first robot was installed, he has chosen to use either a sexed Friesian or Angus beef straw to AI cows at around hour 42.

“Some would go sooner, but we have found the best conception rates are achieved at this point,” he says.

Continuing to seek the benefits of technology and data, he chose to install DeLaval Plus in July 2024. The system analyses herd data and compares it to global benchmarks to highlight any potential cow health concerns.

“Shortly after the install we had nine cows flag up with gastrointestinal issues. We had seen the signs of this, but the technology confirmed our suspicions and enabled us to act faster. The system has also detected sub clinical milk fever and a couple of sub clinical mastitis cases,” he says.

The herd has an admirable SCC of just 60,000 and he has only had one case of mastitis in 2024. Identifying issues sooner has also helped manage supplements such as calcium and magnesium more accurately.

He is assisted by dealer EFS Automation whose representative monitors his farm and six others locally using DeLaval Plus.

“Meabh Byrne looks at the data from all the farms in the area every morning and contacts us if she spots any causes for concern. We are on a full-service package which means all of our consumables and servicing needs are handled by EFS and Meabh often knows what we need before we do and makes sure a technician is on hand to help,” he says.

He recalls that on one occasion the farm needed help on Christmas Eve.

“I have only had two out of hours visits from the technicians in three years but one was at Christmas and they still came out quickly. There are four robotic technicians which means that, even in a busy dairying area like this, there is always someone on hand to help,” he says.

The farm is looking to install solar panels to become more self-sufficient by generating their own energy. However, the focus is very much on bringing the new additions to the herd through their first lactation and increasing the farm’s overall yield.

“It is an expensive time for the farm at the moment because we have 60 first lactation heifers and it’s been a tricky year for forage and grass growth. However, we are sure that once up to the level the older cows are at that we will have a sustainable system for many years to come,” he concludes.

For more information on the DeLaval VMS™ V300 series of milking robots, click here.