New behaviour analysis drives herd productivity

Pioneering behaviour analysis software has been used by the Hyslop family to offset labour challenges and provide the data needed to make decisions that have increased yield at a time when performance margins have been tightened throughout dairying.

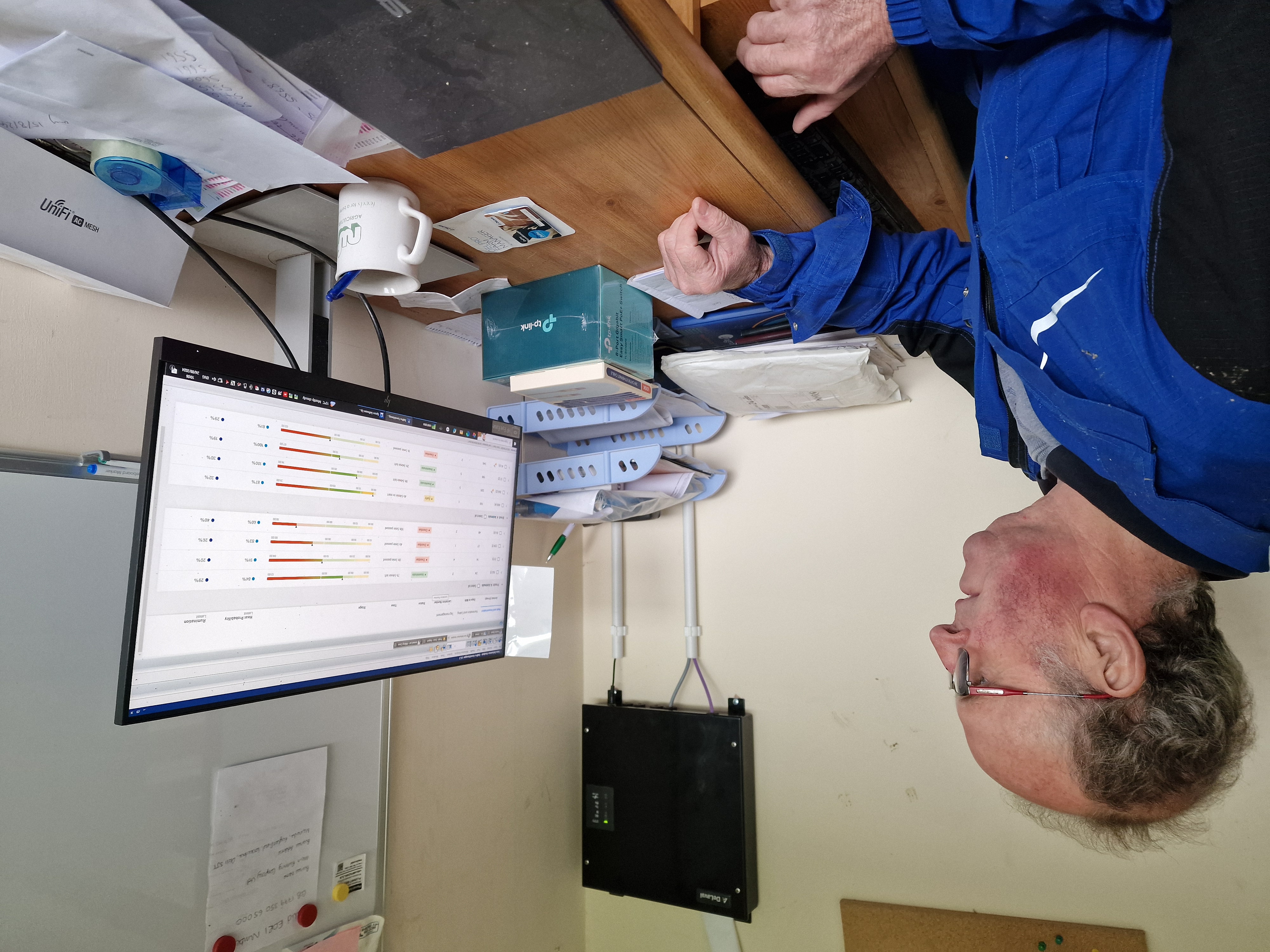

The DeLaval software was installed by Mathers Ltd in January 2024 and has since been used to gather data on cow movement, health, fertility and productivity. David Hyslop suggests that it is providing cow health insight at least 12 hours faster than he, his sons and their staff, could through visually monitoring the herd.

“The behaviour analysis uses ear tags and sensors in the sheds to feedback data on every cow. Using a traffic light system, it raises levels of concern and provides the data to help us and the staff make decisions,” he explains.

Milking information taken from the farm’s 20/40 swingover parlour is combined with cow movement and health data provided by the ear tags to indicate signs of stress, fertility and lameness.

“As part of our expansion we have taken on staff who naturally don’t have the same working knowledge of the farm or the herd as we do. The behaviour analysis data is helping the staff to prioritise cows that need help. It is also helping us to educate our staff and make the most of the labour time we have,” says Mr Hyslop.

The herd has grown from 330 in 2020 to 460 in 2024, with 350 followers. Meinside Farm extends to 750 acres and is located near Eaglesfield, just north of the Scottish border. The herd is milked twice a day, providing a yield of 11,000 litres per cow annually.

“We have a closed Holstein herd, and we are in the process of growing quite rapidly. I feel the pressures on dairying have led us to this. However, I am instinctively entrepreneurial, and I am lucky to have two sons who have worked tirelessly to support our plans for the farm,” he says.

Always keen to benefit from labour and time saving measures, the family installed DeLaval Evanza clusters in 2020 to increase milk and reduce the time needed to change liners. The introduction of the clusters saw SCC’s drop and, today, the average is 130. It has also brought down mastitis cases.

The farm has also invested in other areas to help improve its margins.

“We have installed a renewable energy system which provides ample electricity for the farm. Two combined heating power units use woodchip to power a V8 engine which runs off the carbon monoxide generated in a process called gasification,” he says.

He concedes that finding staff has been challenging in recent years and that expectations of what a working week is have changed considerably.

“We have to appreciate that times have changed, and this is where I see technology like behaviour analysis filling a gap. We can rely on the data generated from the software and share it with our staff to help structure their time and decision-making,” he says.

The farm operates a shift pattern which leads to frequent staff handovers. He sees this as inevitable but also as a threat to how well the farm performs.

Without qualified people with eyes on the cows all day, we risk missing important signs that cow health could be adversely affecting the herd performance. Having the data means the handover from one member of staff to another is seamless,” he says.

The behaviour analysis system can flag up issues for each cow in the herd, including fertility and rumination. The analysis provides accurate bulling behaviour alerts and gives windows for when cows should receive AI. This is shown in 12-hour timelines which pinpoint the optimum time to AI each cow. In addition, the farm is acting on this data to choose better genomics to improve the herd.

“Early alerts for rumination can highlight the onset of a health issue which may include mastitis, ketosis or other health problems. We also have location analysis sensors which accurately help the staff to subsequently find any of these cows and pull them out for treatment,” he adds.

He suggests that farming is becoming more office based, and by sitting in front of a screen or by using the apps on your phone, he can see more than he would be able to in hours with the cows.

“It would have been inconceivable for us to grow the herd at such a rate without the ability to monitor the cows in this way and adjust to improve herd health and boost productivity,” he says.

His belief is that every cow has the potential to be high yielding, and it is how the farm selects, breeds and manages the cows that determines the productivity and longevity of each cow.

“Behaviour analysis has helped us establish the characteristics of cows that are higher yielding and select these to build a stronger and more productive herd,” he says.

The benefits of behaviour analysis are not confined to cows in milk, and Mr Hyslop says that he was able to learn more about how dry cows were coping by using rumination data provided by the system.

“We looked at rumination levels in dry cows and established that this fluctuated as the number of cows in the shed increased. A rumination chart showed the average rumination percentage decreased as cow numbers increased. Essentially, the cows became more stressed as the shed become more crowded.”

Being able to share this information with the team has enabled the farm to better manage cow numbers in sheds and study behaviour on a group-by-group basis.

“We are committed to improving the skill set of the team and help them to learn how cows are reacting to different situations and treatment. We offer our staff courses to improve their knowledge, but having this level of data on farm is also helping them to understand what the herd needs more easily and quickly.”

Mr Hyslop and his sons, David and Martin, who both have played a key role in transforming a family farm into a modern business, believe that technology has been the key to managing this transition.

“With two milkings currently taking almost eight hours each day, we will inevitably have to change our parlour, but the measures we have implemented in the run up to that change are, in my opinion, just as important.”

With the help of the data provided by DeLaval’s technology, the farm will be able to make a more informed parlour choice for both staff and the herd, allowing them to perform at a high standard into the future.

The speed of change on the farm, as it grows, has been an eye opener for the Hyslop family. They installed DeLaval’s DelPro system in November 2023, which was subsequently added to, with the behaviour analysis software and location system, just two months later.

“We are not frightened of making big changes or decisions, but it is for my sons to decide the direction the farm takes in the future, and we are all agreed that using the technology available to us is going to improve our productivity as we grow. DeLaval and Mathers have been instrumental throughout the process, and we have confidence that, as we grow, we can continue to make improvements.”

Farm Facts Meinside Farm

- 750 acres

- 460 milkers with 350 followers

- Butter fat – 4.3

- Protein – 3.3

- Sccs – 130

- 11,000 litres per cow per year

For more information on DeLaval Plus Behaviour Analysis, click here.