Home

Knowledge hub

News & events

News

From vets to farmers:

From vets to farmers: UK’s first DeLaval Optimat™ feeds award-winning sheep cheese production

When John Bailey and Heather Benbow sold their vet practice, they embarked on a lifestyle change that saw them become farmers for the first time. Following the purchase of not one, but two farms, they started milking sheep to make cheese in the Derbyshire Dales.

“I never thought I would be able to retire and just read a book, so after the sale of the vet practice we discussed our options and with a fondness for sheep and a passion for cheese we bought two former dairy farms and applied for planning permission,” says John.

The planning permission was not just for a sheep shed, but for an on-site creamery, hotel, farm shop, charcuterie, bar, restaurant and visitor experience with a children’s petting farm. Wakebridge Farm, in the village of Wakebridge which is close to Crich, home of the National Tramway Museum, has a fascinating history which Mr Bailey saw as another reason to bring it back from the brink.

“The dilapidated buildings date back to the 18th Century, but the history of the farm goes back to the Doomsday book. Former owners of the land include Anthony Babbington who lost the estate and his head when he plotted to assassinate Queen Elizabath the 1st. The estate was also owned Sir Walter Raleigh and Peter Nightingale, an uncle of Florence Nightingale,” he says.

To kick off the farming enterprise John and his family bought 160 East Friesian milking sheep from Germany. The aim was to start milking in 2019, but sadly the pandemic upset their plans.

“DeLaval delivered the parlour and our automated feeding Optimat system, but were subsequently unable to allow their technicians to travel from Sweden to fit the machinery because of travel restrictions. We had 160 sheep that we couldn’t milk and our plans were put back at least three years as a result of a variety of problems caused by Covid and delays with getting planning consent.” he explains.

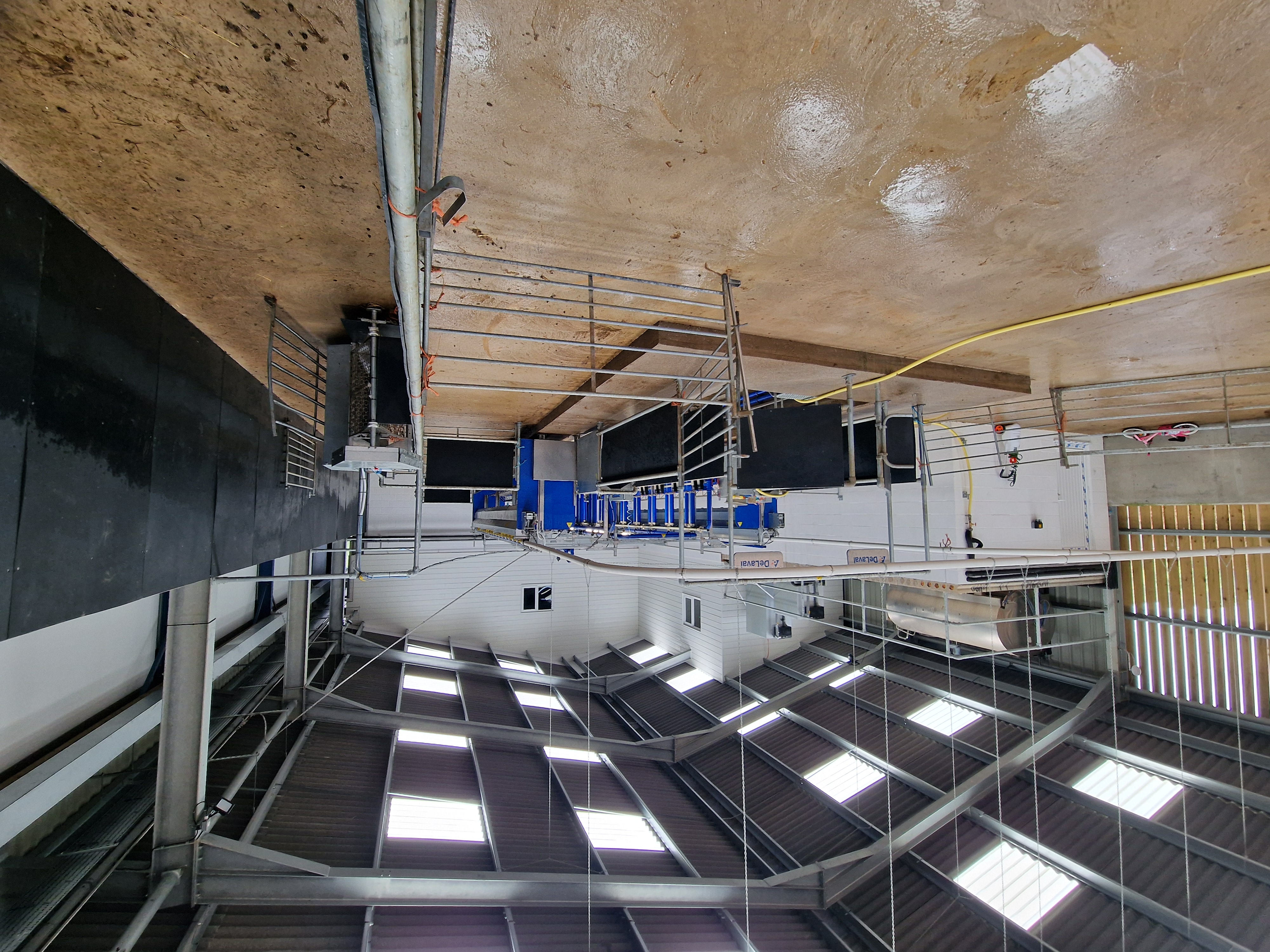

The farm started milking in July 2023 through a DeLaval 36/36 rapid exit parlour and has since grown the flock to 800 ewes. Lambing is three times a year with 85% of ewes that lamb three times every two years. Mr Bailey suggests there will be 650 in milk all year around by the spring of 2025.

“We sell the lambs at six months and will soon start to adapt our breeding to increase lamb size by bringing in Charolais and Texels,” he says.

In April 2024 the farm lambed 400 and, as part of the three lambings in two years system, a further 60 were lambed in July. 300 more due to lamb in November will see the flock ready to milk the 650 target by the spring of 2025.

Mr Bailey farms in partnership with Heather and their children David, Victoria and Hannah all have their parts to play.

“My son David and son in law Dan are our cheesemakers, and Hannah works with her husband Jason to tend and milk the flock. We are all invested in the business and have made it a family ambition to see the farm and all its buildings reimagined for the future,” he says.

He suggests that the initial flock of 160 was a real handful because the sheep were housed in old dairy buildings.

“We had a new building erected to house the sheep because managing feeding was too labour intensive and there wasn’t enough space. As part of the planning for the new building we looked at the DeLaval Optimat automated feeding system to save time and improve nutrition,” he says.

DeLaval’s Optimat system is designed to feed forage and supplements to cows, but the system was adapted to feed Mr Bailey’s flock.

“It has taken the pressure off us and works remarkably well, plus the sheep like it and get excited when it powers up. We load it with silage, hay and concentrate along with mineral supplements and it handles the feeding out and pushing up,” he says.

An OptiWagon robot is fed from Optimat’s mixing and cutting distributor using a conveyor. It then travels around the shed to feed out and push up the forage.

“It is a cost-effective solution for us because we need to keep our labour costs down and we have an ever-increasing flock to feed,” adds Mr Bailey.

The parlour is equally important to his time and labour-saving efforts.

“Hannah and Jason had never milked an animal prior to us moving here and starting the farm with us. However, the parlour is ever so easy to use, and they can milk up to 300 sheep an hour,” he says.

There are cluster removers, and sheep are fed in two drops during milking to encourage them to stay in the parlour until milking has been completed. The ewes have ear tags which provide milk yield data and there is an auto-shedding function at the exit to separate problem ewes into a pen.

He suggests mastitis cases are rare and that they have decided on a cull rather than treat strategy to keep cell counts low. The flock is milked once a day, but he is considering moving to twice a day soon.

“We milk at 6:00am and could incorporate a second milking at around 4:00pm. However, we are uncertain of what yield we will get from a second milking and whether this will be worthwhile when compared to the labour cost,” he says.

The flock is milked for eight months and grazed following drying off. The lactation period yields around 250 litres per ewe milking once a day which with a flock of 650 in milk all year around amounts to 243,750 litres for the whole flock.

“We need 6000 litres to make one tonne of cheese. Allowing for some wastage we have a maximum output of around 40 tonnes of cheese per annum. This is the goal, and we are almost there, I am currently forecasting this yield for 2025,” he says.

To keep up this yield the farm has opted for a Mediterranean style system using teasers to synchronise lambing and breed from the flock three times a year.

“All the ewes are lambed indoors, and all the lambs are given 50ml per kilo of colostrum within two hours of birth by bottle or tube, we don’t ring at all. We breed 20 percent as replacements and the rest will be crossed with Texel or Charolais to produce bigger lambs for market,” he says.

He adds that longer term the farm will introduce a genomic testing program to improve yield and also help manage any potential disease problems.

To further automate the farm, Mr Bailey is looking into a more efficient lamb feeding system.

“At the moment we use individual feeders but these have to be individually cleaned. We are looking at a double pipe feeder that is easier to clean. Milk is piped automatically and there is an inbuilt temperature sensor. Crucially, it also tells us how much milk each lamb is taking which will enable us to identify sick lambs faster,” he says.

Away from the day to days of milking the flock, the family is tasked with making cheese and developing the rest of the site into the visitor attraction that Mr Bailey has applied to build.

“Our son David and son-in-law Dan, having never made cheese before have reinvented themselves as magnificent cheesemakers and filled our creamery with superb maturing cheeses that we sell locally and will soon sell on-line, through other mainstream retailers and from our own shop,” he says.

The farm makes a variety of sheep milk cheeses. Wakebridge White is a clothbound pressed sheep cheese with a rich mellow and rounded flavour.

“It won gold at the International Cheese and dairy awards and the judges commented ‘a beautifully presented Cloth bound cheese. Wonderful deep cream nutty nose. In the mouth this cheese produces waves of delight. It just keeps giving’,” says Mr Bailey.

Further varieties include Hey Ewe, a younger, sweeter version. Blue Baa-bara 9, a mild creamy sheep’s cheese, which is sweet with a distinctive blue taste. There is also a blue veined cheese called Wakebridge Blue which has a rich, strong flavour.

“We also buy in cows’ milk to make our Derwent White, an old style Derby cheese and Derwent blue a creamy blue veined cheese,” adds Mr Bailey.

Located a few hundred metres from the popular Crich Tramway Village, he hopes that by adding accommodation, a bar and restaurant that the farm can attract tourists to spend some time and money as part of their visit to the Derbyshire Dales.

“Our choice to farm and invest in this site is one we want to share. Visitors will be able to stand on a viewing platform to see the sheep being milked and can enjoy our cheese in our onsite bar and restaurant. We will also be selling the cheese and local produce in our farm shop,” he says.

Whilst the full extent of the farm’s portfolio of businesses is still to be realised there is also room for growth for the flock.

“We could extend the shed; we have left space to do so and grow to milk 850. For now though it would be good to consolidate what we have, finish developing the site and start marketing ourselves as a visitor experience. The cheese is already selling well through local delis and shops but it will be great to sell it here from own shop in the near future,” he concludes.

For more information on the DeLaval Optimat™ total feeding solution, click here.