Give Shelter From the Storm

Even if you already have a plan in place, it’s a good idea to revisit best practices from time to time. The consequences of frigid conditions can be devastating for cows and can potentially last through the year, especially Staphylococcus aureus infections.

Winter’s effect on teat health

A teat’s condition can change with cellular stress. Rapid dehydration leads to skin cell disruption, followed by a loss of natural moisturizing. In an effort to compensate, skin cells start overproducing and slow down the natural renewal process of exfoliation. The result is a thickening accumulation of old cells, which forms a flaky layer of dry skin.

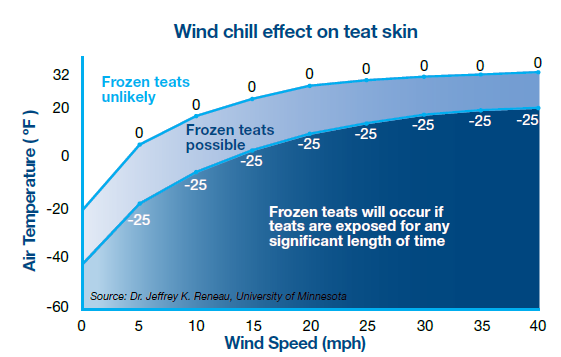

Additionally, teats may outright freeze under certain conditions. Studies have shown that wind chill matters more than ambient temperature. If the wind chill remains above 0°F (-18°C), frozen teats are unlikely. Between 0 (-18°C) and - 25°F (-32°C), frozen teats are possible. If the wind chill is below - 25°F (-32°C) and teats are wet, they can freeze in less than one minute!

Even without the potential for frozen teats, skin that is flaky and chapped is compromised and the risk of infectious diseases, such as Herpes mammilitis, Pseudocowpox and Papilloma (teat warts), increases. Heifers and fresh cows are at a higher risk. With temperature and wind chill as the major predisposing factors to winter teat changes, a producer’s main objective should be to control exposure to weather stressors as much as possible.

How to avoid frozen teats

- Reduce cold-weather exposure. Drop curtains in free stalls to reduce wind speed and help eliminate wind chill. Avoid drafts by controlling ventilation and check for malfunctioning curtains. Also, check for doors left open in tie-stall and stanchion barns, which can create tunnel ventilation. If animals have to go outside, provide windbreakers.

- Keep stalling clean and dry. Having comfortable, dry areas or stalls for animals is critical to teat health, so keep bedding clean and dry by changing it frequently. Wet bedding not only increases body-surface heat loss but also leads to wet teats and potential frostbite.

- Maintain proper function of milking system. In the parlor, the milking machine is a teat stressor. At a time when teats may already be stressed by the cold, proper functioning equipment is essential. High vacuum levels and/or fast pulsation rates result in poor blood flow and inadequate teat massage. Avoid over-milking and clean and sanitize equipment after each milking session.

- Use post-teat dips to disinfect and condition skin. Some producers stop post-dipping teats when temperatures drop below freezing because they think cold weather decreases bacterial growth. Studies have shown that eliminating teat disinfection actually increases the spread of contagious mastitis pathogens. Therefore, it is important to continue an efficient teat dip program to assist in mastitis control during the winter months. It may also prolong good teat-skin condition from winter into spring and potentially reduce SCC fluctuations. In freezing temperatures above 20°F (-7°C), conditioning pre/post teat disinfectants should be used, as they are designed to improve overall skin condition, teat-end health and reduce hyperkeratosis. Conditioning agents in teat dips reduce the potential for chapped skin, which minimizes the chance of bacteria entering the teat canal. When temperatures fall below 20°F (-7°C), producers should consider using a high emollient winter teat disinfectant.

- Practice good hygiene. Gloves and individual towels should be used at all times, and teats should be completely dry before milking. Water use should be minimal as it enhances chilling. After dipping with a disinfectant, that has a proven germicidal efficacy, gently blot irritated skin as opposed to rubbing it. This will help minimize damaged, cracked teats.

- Give teats time to dry after post-dipping. Avoid exposing animals to extreme wind chills after post milking teat disinfection to allow time for the product to dry. If this is unavoidable, try blotting off excess disinfectant. It is important to monitor teat skin of fresh animals because they are more susceptible to chapping and freezing. Do not use barrier dips in extremely low temperatures as they normally take longer to dry.

- Store teat disinfectants according to manufacturers’ recommendations. Often forgotten in a winter management program is the proper storage of teat disinfectants. Some products may freeze if stored in uninsulated, unheated buildings. If freezing does occur, it may affect the chemistry of the active ingredient(s). Thawing may or may not affect the product’s properties, so producers should check with the manufacturer for specific information.

Protecting teat health during the winter months can take additional time and planning. However, the rewards can far outweigh the inconvenience.