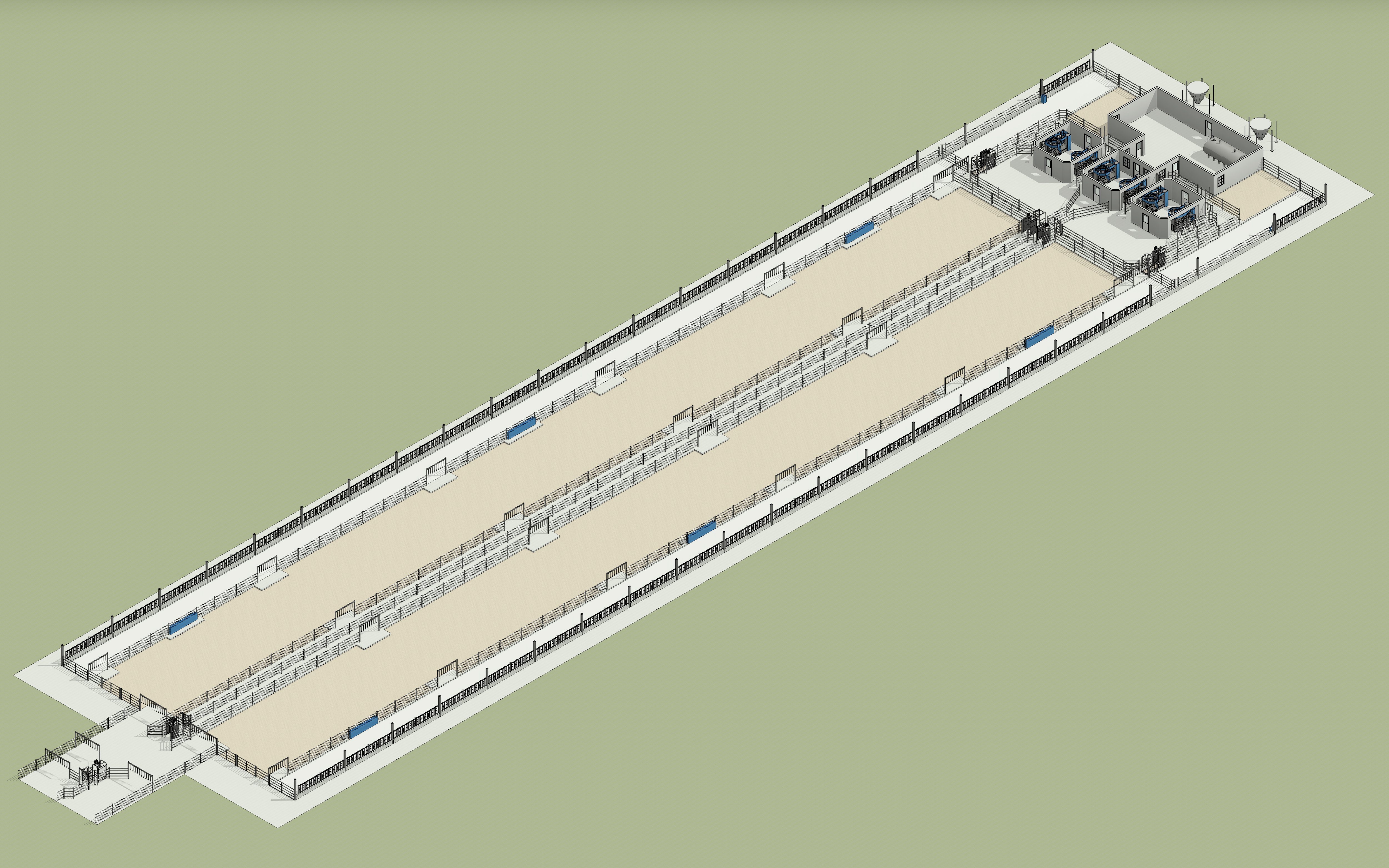

A Closer Look at a Robotic Barn with Access to Grazing

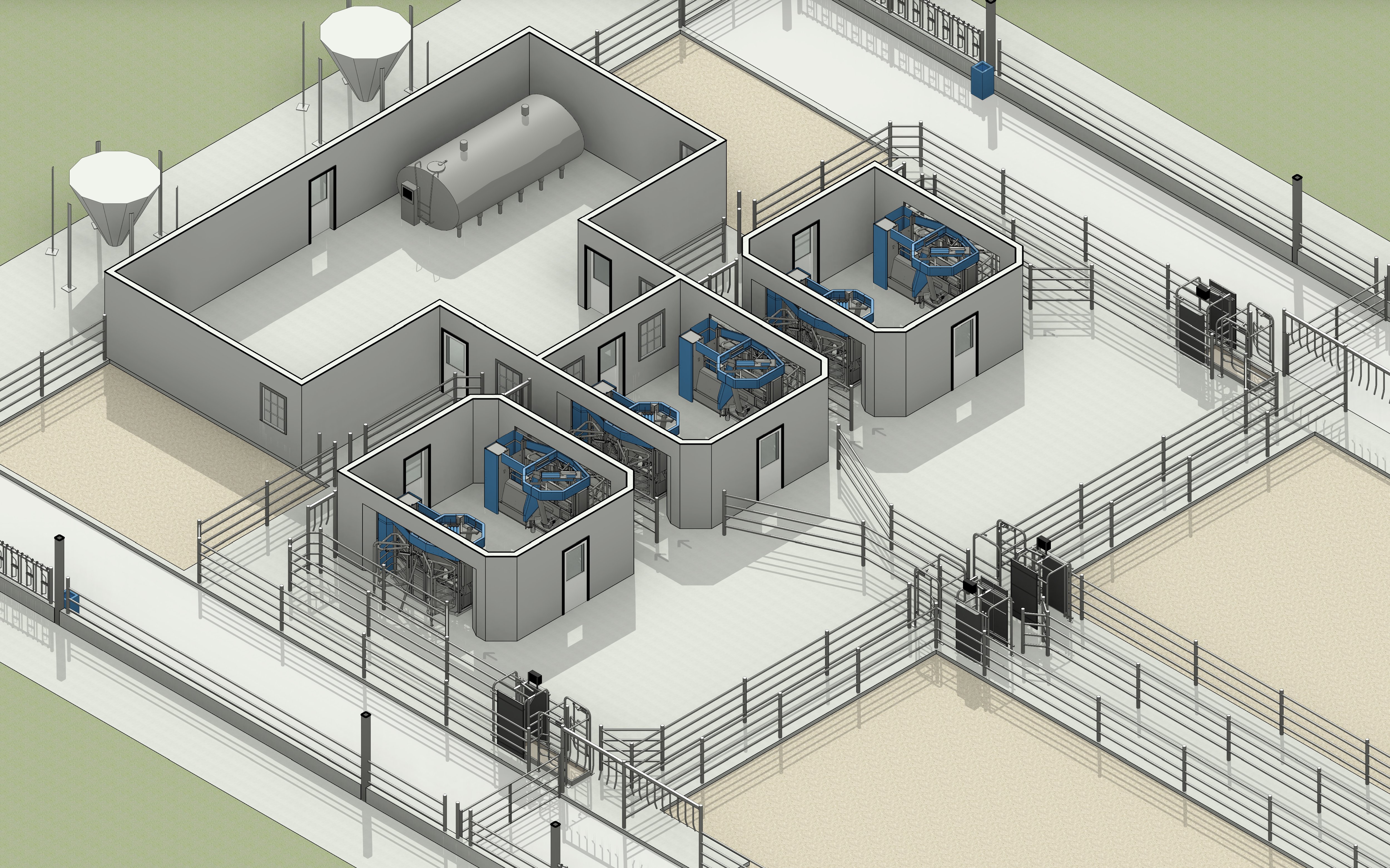

At the milking area, the robots are arranged in a toll-gate style when cows enter from one size called the Commitment Pen and exit on the other side. The advantage over a tandem arrangement, where robots are nose-to-tail, is realized most when there are multiple robots milking one group of cows. First, the cows exiting into away from the Commitment Pen eliminates co-mingling. The issue here is cows waiting to be milked are mixed with just milked cows leading to a congestion. Second, sorting cows is facilitated. In a tandem layout with multiple robots we either have to co-mingle cows in the Commitment Pen then sort using an exit Smart Selection Gate, or sort through adjacent robots. This is typically acceptable in a free flow layout where maximizing capacity (time milking) is not necessarily desired. In milk first we are allowing only cows with milk permission into the robots, thereby maximizing capacity.

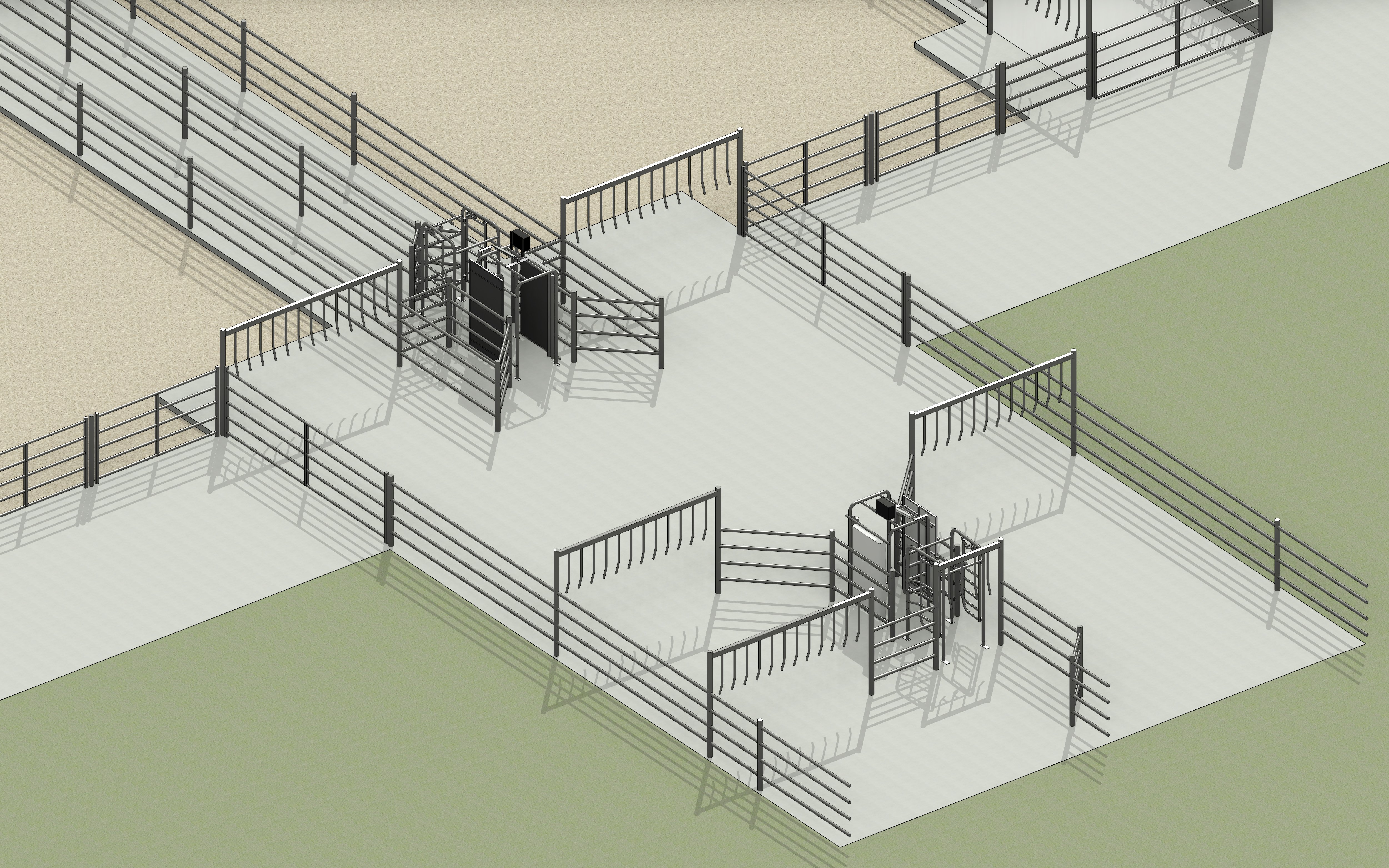

Another benefit of this design is AB grazing. That means cows from either group can freely exit the barn to enter a designated paddock that is open, then are sorted back into their respective groups when reentering the barn through the Smart Selection Gate. Upon reentering the barn, cows go directly to the entry Smart Selection Gate at the milking area via a grooved concrete lane. There are two benefits to this: 1) cows with milk permission go to the VMS immediately while those that don’t are sorted to the feed alley 2) the quality of the bedded pack is preserved when cows reentering the barn do not go directly into the pack at one point.

Although this design was prepared for a specific dairy that is retrofitting an open air barn that is covered by a shade, it can be adapted to a greenfield build as well.