VMS™ delivers more

With VMS it all revolves around you: Which is why we have developed the VMS to be the world’s most flexible milking robot – so that it works for you, and not the other way around. DeLaval VMS™ is designed to deliver more, better quality milk, healthier animals, and more freedom for you.

Farm more profitable

Our system is designed to help you produce more milk, more efficiently, more safely and more sustainably, in a way that also meets the consumer pressures that farmers the world over are facing today. Automatic controlled milking permissions can additionally lower your use of energy, water, teat spray and labour.

Milking only starts if it’s beneficial

A VMS™ from the V300 series doesn’t just milk every cow, regardless of the economic value. It calculates permission based on a combination of her yield and the time since her last milking.

This means it only milks those cows for which another milking will be beneficial, which can result in a better yield and better udder health. For some this may mean a 4th milking at 3am, for others in the same group, only twice in the same day. If she is given permission to be milked, she is delivered a customised supplement feed mix, if not – no concentrate is given and she is exited seamlessly from the VMS™ so that the next cow can enter.

Most of all, VMS™means healthier, happier animals - resulting in a lower cull rate and a real possibility of more lactations per cow. And with VMS™ V310, accurately managing reproduction is as good as money in the bank.

See how Travis increased profitability his way.

Real Quarter Milking

Incredible gains for productivity

Better Information

During milking you can observe milk flow, yield, blood and conductivity and milking interval as well as other key production data; all per quarter, and all compared to last milking.

Smart Pulsation

VMS™ constantly measures each cow’s milking performance and adjusts the pulsation ratio accordingly to milk her. The result: faster and less stressful milking, which allows for more milkings per day and shorter waiting times for cows.

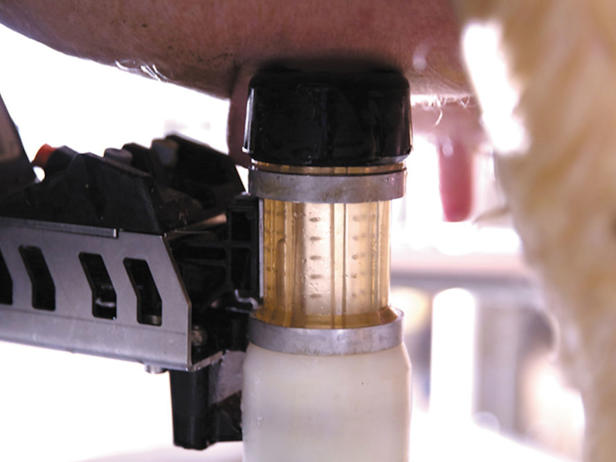

Stable Vacuum

With short milk tubes and a good working vacuum system, the VMS™ provides a good vacuum stability, which leads to better comfort, milk transfer and fewer slips or kick-offs. The shorter tubes also reduce maintenance costs.

Better Take-off

The advanced modeling, combined with the real time flow data from the 4 ICAR approved milk meters makes it possible for VMS™ to detach at the right time, in the right way to protect the sensitive and valuable teats.

RePro™

The complete reproduction management tool

Getting cows in calf is central to everything we do on a dairy farm. So you want to be certain that fertility is at the heart of any system.

DeLaval RePro™ is designed to create a clear picture of each animal’s reproductive status using BioModels to interpret the progesterone level in milk samples taken automatically by your VMS™ V310. Does she begin to cycle after calving? Is she really in heat (even a silent heat)? Does she have a cyst? Is she now pregnant or has she had an early abortion?

All these critical questions are answered automatically and notifications presented to you, which may mean healthier cows, reduced vet costs, improved insemination costs and cows becoming pregnant at the right time resulting in more productive lactations – which you know means more money.

RePro™

Automatic heat and pregnancy check

- More productive lactations

- Reduced culling

- Notification of early abortions

- Fewer open cows

- Detect abnormal reproduction cycles

Animal Welfare is key

Healthy, calm cows are the key to milk volume, milk quality and to the profitability of any dairy farm. You can see this when you observe how calm the cows are in a VMS™ system, everything happens quickly, smoothly in a stall that is comfortable, clean and consistent.

A consistent and calm milking process

The milking process in your DeLaval VMS is consistent, calm, and focussed on delivering the smoothest milking for each cow.

- Stall design allows excellent cow flow and cow positioning

- Adjustable stall (flex concept)

- Relaxed environment

- Smooth hydraulic robot arm

- Accurate teat spray with DeLaval InSightTM

- No cow can leave the station without being sprayed

Watch the video to see how Jeremy manages animal health his way.

Working with Nature

When a cow enters the VMS™ she will have a small amount of milk already in her udder and teat cisterns ready for evacuation. This will be about 45 seconds worth of milk. The true flow of milk however, will not begin unless oxytocin has been released and is squeezing the cow’s alveoli.

To help consistent milk flow by stimulating Oxytocin release, VMS doesn’t just clean the teat, it prepares it for milking by using a combination of teat spray for disinfection and the DeLaval PureFlow™ cup for proper cleaning. It stimulates oxytocin release and facilitates milk ejection before vacuum is applied to teats by means of a combination of water (or cleaning solution if desired) and air.

This results in a superior flow pattern and less time with cups on, which is great for udder health.

In numbers

- Get up to 99% teat spray hit

- Get a possible extra lactation of out of cows

- Avoid mastitis and achieve low cell count

To help improve the quality of your milk and welfare of your cows, VMS™ makes hygiene and cleanliness a top priority.

- Clean and dry the teats with the dedicated PureFlow™ preparation cup

- Automatic floor cleaning

- Automatic camera cleaning to avoid cross contamination

- Automatic shut-off valve in case of kick-off

- Smart cleaning vessels to secure the cleaning process

- Automatic optimising of the cleaning process

Improved work efficiency; do more with less

With an industry-leading average of 66 cows per station, VMS™V300 series does more with less. Less labour, less energy, less water, less hassle.

The VMS V300 series provides the opportunity to create a better work environment and lifestyle for you and anyone who works on your farm. This will help you increase your milk production per labour hour.

- Eliminate repetitive task of manual milking to create time for high value tasks

- Schedule tasks on your terms at times that suit you

- Automate as many repetitive manual tasks as possible

- Increase your milk per labour hour

- Focus on cow welfare, productivity and reproduction management

- Staff attraction and retention benefits

See how Mitch maximizes efficiency his way.

Farm smarter

Make informed decisions about your farm performance from the fast, accurate and actionable data delivered by DeLaval DelPro™, and in the case of VMS V310, DeLaval RePro™.

On the day you install it, your VMS™ from the V300 series will be the best milking system you can buy. And the good news is that it keeps performing even better over time, with the possible use of artificial intelligence and software enhancements.

See how Rodney farms bigger and smarter in his way with VMS.

Do more with your data

At DeLaval we understand that dairy farming is a process. It is ongoing, relentless and it demands fast, accurate information so that you can make the best decision for your performance. That is what DeLaval DelPro™ delivers.

Your VMS™ from the V300 series captures a huge amount of raw data at every milking. Without the tools to process and analyse it, some of the most valuable performance data available is not fully utilised, or worse – wasted. That’s where DeLaval DelPro™ can unlock the value hidden in your data.